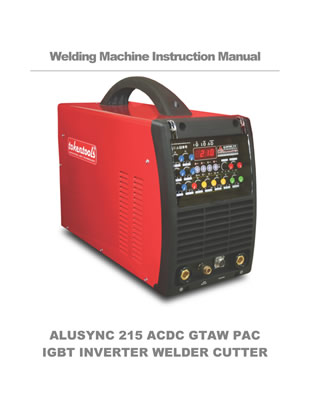

AC DC Tig Welder - The Alusync 200 was an awesome machine however we just wanted to tweak it a bit more. The NEW Alusync 215 is even better and built on the same sturdy and dependable IGBT inverter transistor welding core but with a digital back end and a front panel full of ADC's, Analogue to Digital converters. Fusing the appeal of gentle control via knobs and at a glance settings recognition with accurate digital microprocessor control. We have also adapted some of the features from the Elite and Pro range of machines such as FOD, Fan On Demand. Did we mention the flip up front clear plastic cover that protects the control panel from debris?

The new Metalmaster Alusync 215 Inverter ACDC Pulse Tig Welder and Plasma Cutter is a 240 volt, full arc control, AC & DC TIG Welder / MMA Stick Welder, HF TIG power source with integrated 210 Amp Tig and 50 Amp Plasma Cutter. Standard features on this machine include high frequency arc ignition, up and down slope, start amps and crater amperage settings, pre flow, post flow, adjustable AC frequency with a massive 20 to 250Hz range, high and low pulse welding modes, repeat (latch) function, MMA welding and integrated plasma cutter functionality.

The Metalmaster Alusync 215 multi function welder cutter is designed to be an all round product suitable for precision TIG / MMAW and plasma cutting of all weldable materials. The Tig Plasma machine features push button activated HF Arc Ignition and a Gas Solenoid for automatic control of the shielding gas. A large capacity fan that switches on and off when required ensures years of high duty cycle operation. Operation is quite straight forward via the oil /acid resistant membrane control panel and the steel case will provide superior protection against accidental bumps.

All IGBT transistors are manufactured by Infineon, chosen for their ability to provide dependable power in the toughest of environments. With the Metalmaster Alusync 215 you will have one inverter TIG MMA welder and plasma cutter ready to attack and conquer any job you put to it.

Brief Overview

- New

- Metalmaster

- 5 Years Parts & Labour

- 1 x 240 Volt 15 Amp Supply - Single Phase

- AC Tig Welding

- DC Tig Welding

- Pulse Tig Welding

- DC MMA Welding

- Plasma Cutting

- 2T / 4T Trigger Latching

- Pre Flow Shielding Gas Timer

- Adjustable Start Amps

- Adjustable Finish Amps

- Welds Aluminium

- Welds Stainless Steel

- Welds Other Metals

- Cuts all metals

- Adjustable AC Welding Frequency

- Adjustable AC Balance / Cleaning Action

- Pulse Welding Mode

- Adjustable Pulse Width / Duty

- Adjustable Pulse Welding Frequency

- Arc Force

- Post Flow Shielding Gas Timer

- Up Slope

- Down Slope

- Push Button Start HF Ignition

- Preset Amps Control / Display

- Digital Readout

The inverter welder design is either IGBT or MOSFET

- IGBT - Siemens / Infineon Power Transistors

- L50cm x W23cm x H44cm

- Weight - 25 Kilograms

Plasma Cutting Features

- HF arc ignition

- Cuts all metals

- Clean cut to 16mm in mild steel

- Severance cut to 20mm in mild steel

- Requires 60PSI compressed air

- Requires 7CFM of compressed air

- Includes filter / dryer (water trap)

- Rear Mounted Air Pressure Gauge

Tig Welding Features

This is the method of arc ignition. It consists of pushing the start button on the torch to enable an automatic arc strike.

- Push Button Start (HF)

The ability to activate and deactivate shielding gas and also provide post flow

- Electric Solenoid activates when torch trigger is pressed

- Preflow - 0 to 10 seconds

- Postflow - 0 to 25 seconds

The settings that enable control of the welding waveform

- AC Square Wave Frequency - 20Hz to 250Hz

- AC Balance - 10% to 90%

- AC & DC Pulse Width

- AC & DC Pulse Frequency

- DC Amps 5 to 210

- AC Amps 10 to 210

AC is used for aluminium welding and DC is used for other metals

- AC Square Wave

- DC

Amperage and frequency range available when using pulse welding mode

- Pulse Duty - 10% to 90%

- Pulse Frequency - 0.5Hz to 25Hz

- Pulse Frequency - 25Hz to 250Hz

A feature required if you wish to use a variable amps torch or else a foot pedal

- Yes

- Foot Pedal Compatible

- Variable Amps Torch Compatible

Slope control is used to increase amps over time from crater amps to welding amps (up slope) or from welding amps to final crater amps (down slope)

- Down Slope - 1 to 25 seconds

- Yes

- Up Slope - 1 to 10 seconds

- Start Amps - 5 to 210 Amps DC Welding

- Finish Crater - 10 to 200 Amps

MMA Welding Features

- 10 to 170 Amps

Duty Cycles

- 160 Amps @ 100% Duty

- 210 Amps @ 60% Duty

- 100 Amps @ 100% Duty

- 140 Amps @ 60% Duty

- 160 Amps @ 35% Duty

- 30 Amps @ 100% Duty

- 50 Amps @ 60% Duty

What is in the box?

- 1 x Alusync 215 Inverter Welding Cutting Power Supply

- 1 x 4 Metre 60 Series Ergonomic Plasma Cutting Torch

- 1 x 4 Metre Binzel Compatible 26 Series Ergonomic Tig Torch

- 1 x 3 Meter MMA Twist Lock Torch and Cable

- 1 x 3 Meter Job Clamp and Cable

- 1 x Reinforced gas Line

- 1 x Filter Dryer (Water Trap)

- 1 x Plasma Torch Accessory Kit (5 tips, 5 electrodes, 3 ceramic shields)

- 1 x Tig Torch Accessory Kit

- 1 x Instruction Manual

This welding machine includes a 5 year (60) month warranty against manufacturing faults and defects however the customer has the ability to reduce the warranty period in order to obtain a greater discount. In circumstances where the customer elects to take a 2 Year or 1 Year warranty the 5 Year warranty will no longer apply and instead the selected warranty period along with applicable discount will apply and such direction will be noted on the sales invoice.

Our products are typically despatched from our warehouse on the same day if payment is made before 2PM.

All of our orders are despatched quickly. We don't like you to wait for your purchases. In fact over 90% of deliveries to major metro areas across Australia's East Coast arrive within 2 business days from the day we confirm payment (that's same day for credit card and PayPal orders). West Coast orders take 4 days longer. If you live in a regional area then we suggest you allow up to 4 additional days for your goods to arrive. A tracking number will be emailed to you upon shipping of your product and you will be able to get an ETA delivery date from that source

This welding supply is also available for pickup from our showroom located at Unit 6, 9-11 Willow Tree Rd Wyong NSW 2259 during opening hours. See the pickups information for more details.